What makes a core drill bit dull?

If you found this post then you have a problem. Your core drill bit is dull. I am specifically speaking about wet-cutting with diamond embedded teeth core drill bits. The type used on core drill motors that are in general are 120 volts, 15 to 20 amp, and made to drill holes in reinforced concrete walls, footers, brick walls, concrete floors, and foundations on construction sites or households.

Theoretically a core drill bit is supposed to be self-sharpening. Embedded diamonds in the metal teeth of the bit becoming exposed as the metal holding the diamonds gets ground away in a circular motion cutting the concrete.

Possible non-core drill bit related causes.

- Use the correct core drill motor for the hole size being drilled. Every electric-powered core drill motor has a rating for the size hole it is capable of drilling starting from smallest to largest. This is related to the RPM of possible speed settings if so equipped.

- Enough water pressure to push the slurry out of the hole. The way core drilling works is for the water to come through the water inlet down the spindle into the interior of the core drill bit where it cools the teeth and expels the slurry

- Hooking to the right electrical connection Most electric-powered core drill motors need a minimum 30 amp breaker to drill hole sizes larger than 3-inch.

- The core drill bit has already drilled too many shallow holes. When engaged in coring not only do the teeth of the bit become worn away but also the metal of the interior and exterior of the bit barrel itself. In other words, the bit becomes smaller at the tip.

If none of these issues are adding to your dull core drill bit problems

and you already know that not using enough water is the fastest way to glaze your bit.

And that too much water will not let the bit get warm enough to cause the friction needed to wear away the metal composition of the diamond teeth and expose new diamonds for cutting.

Or, is it summertime? Water running through a garden hose heats up in the summer sun. If the water is too hot the bit will glaze quickly.

Notable disclaimer

Not all the methods to sharpening a core drill bit presented in this article would you find on a recommended list of ways to correctly put an edge to your bit. But you have tried those methods already and that's why you are here.

Common Causes

Too much pressure

most likely caused by misalignment of the core drill rigs carriage and shaft.

Check to see if the base hasn't slightly moved or that there is too much play on the carriage. Also if you are using a small shaft rig and bend the shaft too much it will cause it to drill harder.

Wrong grade of core drill bit

Opposite of what most people think in core drilling terms soft bonds for hard materials and metals. Hard bond for soft materials.

Check to see if your supplier has access to the type of core drill bits you need. Most suppliers and retailers will stock general grade, medium bond core drill bits. This may not be what you need.

Not enough pressure

most likely you can not lock your rig down because of the material being drill.

Contrary to the good book of core drilling, not always can you lock, anchor, or vacuum seal your core drill base down to what is being drilled.

Traditional core drill bit sharpening methods

Using a cinder block

If you read the handbook when you bought your machine the traditional way to sharpen up a core drill bit is to run your bit dry through the cinder block a few times and this will expose new diamonds.

Lessen water flow for a short time.

Slow the water flow down to a trickle, apply a bit more pressure on the handle, and slowly add water as the bit picks up speed and starts cutting again.

Add coarse sand to the hole in the kerf and lessen water flow as aforementioned

How we keep our bits sharp

Start the core drill, touch the bit to the concrete and slowly turned the water on until it reaches one-quarter inch deep then set the water valve open enough to have good running pressure the size hole you are drilling and your bit should stay sharp. Check the color and temperature of the slurry so make sure the bit stays cool but not so cool that it won't refresh the diamond matrix.

Non-Traditional core drill bit sharpening methods

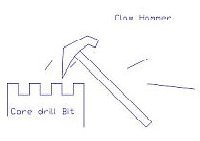

Using a claw hammer

If you are like most core drillers a cinder block is not available or the option of lessening the water advice just is not working. In the picture above you see the bit turned upside down and a claw hammer gently tapping on the edge of the teeth to chip away some of the metal holding the diamonds so they can be freed to cut again. This idea is offered because many core drill projects are done by someone who does not operate a core drill very often and is in a pinch and the most common tool is the claw hammer. Please! Do not hit them so hard they will break but a few good licks should roughen up the teeth enough to cut a little better.

Slightly score with a grinder.

In the video one of the crew is sharpening a 7-inch core bit. What you want to do is make scores across the diamond embedded teeth, not too many but just enough to be able to let new metal become exposed and wear away as the core drill bit cuts the concrete hole. The claw hammer method is not quite as effective but works just well in a pinch. Another trick for sharpening a wet cutting diamond core drill bit is to pour a little dish soap in the kerf of the cut hole and a smidge of water to make an abrasive paste that will deglaze the bit and let it cut better.